In 2008.....

In 2008.....

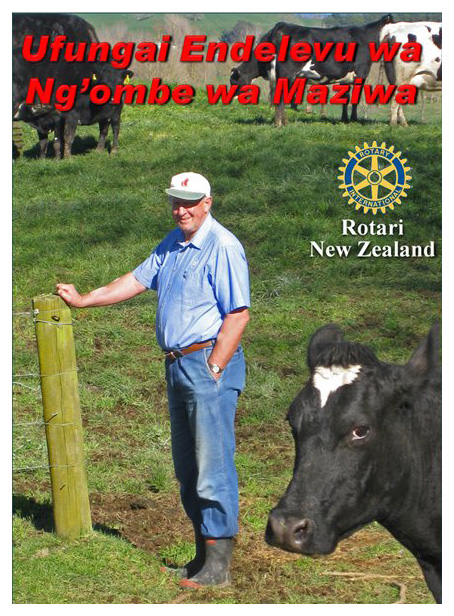

Geoff Mathis, (a Rotarian based in Mount Maunganui, NZ) then Rotary District Governor had an idea, one that required kiwi ingenuity and farming expertise. Geoff developed a simple biogas digester (cow manure in one end – gas out the other end) to help the village of Mwika have access to lighting and cooking gas.

Mwika, on the foothills of Mt Kilimanjaro, is an area of approximately 14sq kilometres. Seven villages reside here, totalling a population of around 7,000 families. Of these, 95% have no electricity or transport. Most families own 1-2 cows.

During 2008/09 Rotary district 9930 donated $19,000 to install approximately 30 digesters for the use by the cow farmers in the village – the farmers paying half the cost of each installation. To date, 94 digesters have been installed.

This part of the project was substantially life-changing for the families of Mwika who now have the resources for gas lighting and cooking.

Not only was Geoff able to educate them on cow nutrition - changing diets at no extra cost, but on the trial farm increased milk production from 7 litres per day to 24 litres per day (over 300% increase in two years) allowing extra milk to be sold to the newly formed Mwika Dairy Co-op Society Ltd to be processed into saleable pasteurized milk products.

A VISIT IN 2010

Paving the Road Towards a Better Future

With the successful installation of the digesters, Geoff saw the next problem to be solved.

Utilising a MFAT (Ministry of Foreign Affairs & Trade) grant of almost $300,000 plus additional "friends of Rotary monies" a small 600 ltr per hour processing plant was installed replacing the copper boiler of yesteryear, including a pasteurizer, cream separator, storage tanks chiller room and a 250 gram pouch sachet packing machine. A major building upgrade was also achieved.

During a visit to Mwika in 2010 Geoff saw milk from the farmer co-op being pasteurised in an old copper boiler. Milk was being delivered to the co-op in Dulux paint tins, detergent containers and other unsatisfactory vessels. Through Rotary 190 five and ten litre stainless steel milk cans were delivered to the co-op (our milk tankers).

A follow up visit in 2013 saw a Rotary Global Grant come through of almost $400,000 enabling a lot of follow up work to be done, more cows purchased , more digesters installed, further factory improvements to satisfy Tanzania Dairy regulations and the list goes on.

A property company has been signed off clearly defining percentage ownership between the church approx. 35% and farmers 65%. The dairy co-op shareholding has been allocated to groups of farmers on 1st Feb 2019.

With further support from MFAT and a substantial Rotary Global Grant they were successful in putting together sufficient funds to purchase 150 black and white heifers – mainly out of Kenya – again farmers paying half of the cost.

Milk production in the collection area has increased from 350 litres per day in 2007 to 3400 litres per day. We expect to hit a target of 4,000 litres by July 2019.

The focus of this project was to allow ownership of all phases of the project to be in the hands of the locals - "We did not give them the fish, we have enabled them to use the tools provided to learn how to fish - in this case it was how to produce extra nutritional milk products, professionally heat treated and marketed in a manner that improved the well being of the families and the community." " That has been achieved," said Geoff

A VISIT IN 2010

Paving the Road Towards a Better Future

With the successful installation of the digesters, Geoff saw the next problem to be solved.

Utilising a MFAT (Ministry of Foreign Affairs & Trade) grant of almost $300,000 plus additional "friends of Rotary monies" a small 600 ltr per hour processing plant was installed replacing the copper boiler of yesteryear, including a pasteurizer, cream separator, storage tanks chiller room and a 250 gram pouch sachet packing machine. A major building upgrade was also achieved.

During a visit to Mwika in 2010 Geoff saw milk from the farmer co-op being pasteurised in an old copper boiler. Milk was being delivered to the co-op in Dulux paint tins, detergent containers and other unsatisfactory vessels. Through Rotary 190 five and ten-litre stainless steel milk cans were delivered to the co-op (our milk tankers).

A follow-up visit in 2013 saw a Rotary Global Grant come through of almost $400,000 enabling a lot of follow up work to be done, more cows purchased, more digesters installed, further factory improvements to satisfy Tanzania Dairy regulations and the list goes on.

A property company has been signed off clearly defining percentage ownership between the church approx. 35% and farmers 65%. The dairy co-op shareholding has been allocated to groups of farmers on 1st Feb 2019.

With further support from MFAT and a substantial Rotary Global Grant, they were successful in putting together sufficient funds to purchase 150 black and white heifers – mainly out of Kenya – again farmers paying half of the cost.

Milk production in the collection area has increased from 350 litres per day in 2007 to 3400 litres per day. We expect to hit a target of 4,000 litres by July 2019.

The focus of this project was to allow ownership of all phases of the project to be in the hands of the locals - "We did not give them the fish, we have enabled them to use the tools provided to learn how to fish - in this case it was how to produce extra nutritional milk products, professionally heat treated and marketed in a manner that improved the well being of the families and the community." " That has been achieved," said Geoff